Hardware Development

If your organization is intended to develop electronic hardware that needs to be in compliance with international standards (e.g. EMC, functional safety, electrical safety, etc.) and needs to be deployed on a regulated market (e.g. in the EU), the following questions might sound familiar to you:

-

- Which are the applicable international safety and product standards?

- Do you have an appropriate hardware development process?

- Do you have requirements and are those correct and complete?

- Is there any requirement management at your organization?

- How do you plan the verification and validation activities?

- Is the hardware architecture documented?

- Is the hardware design documented?

- Is your team experienced enough to avoid common design errors?

- Is there any configuration management at your organization?

- Do you have a change management process?

- How do you handle complaints and field failures?

- Are the design and the related documentation correct and complete?

- Is there enough independence between design/implementation and verification/validation?

- How do you provide evidence to your customer and to the certifying organizations that your product meets the associated standards?

We at ASRP-Systems have over 17 years of professional experience in automotive and industrial electronic hardware development. In the past 11 years, we have been working mainly on safety-related circuits. In many of these projects we worked together with our customers, partners as well as with independent certifying organizations like the TÜV Nord, TÜV Rheinland, and exida LLC.

We are ready to assist you and your team to cope with the hardware development activities as follows:

Documentation

Our customers rely on our expertise in preparing documents as follows:

-

- Requirement specification

- Hardware architecture document

- Hardware design document

- Hardware test specification

The existence of consistent hardware documentation is necessary for professional development. Good documentation reduces the likelihood of the project failing. Without documentation there is a much higher risk for:

-

- wrong design decisions (due to missing requirements)

- systematic failures (due to missing design calculations, explanations, etc.)

- communication issues (with stakeholders, team members, certifying organizations)

- increasing development cost and time (due to the increasing number of required re-design cycles)

- loss of knowledge (due to fluctuation)

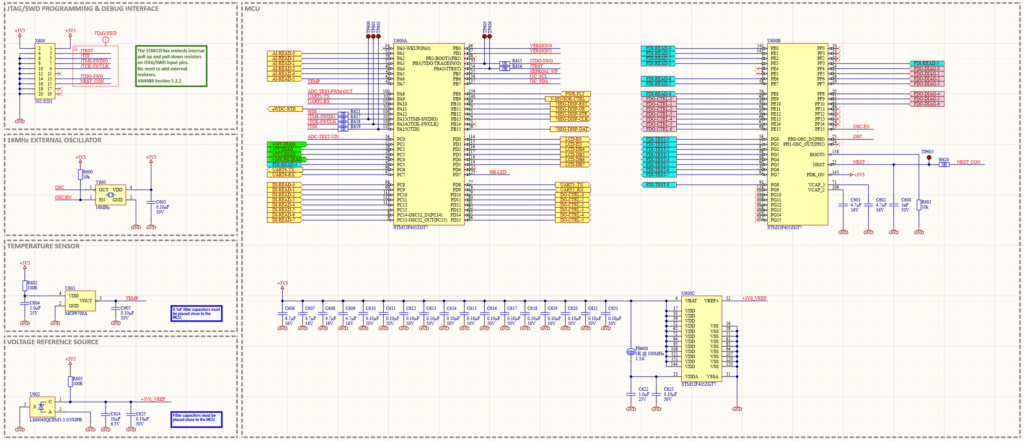

Circuit and schematic Design

To handle complexity and to achieve a clean schematic structure we prefer to use the so-called top to bottom design method. In our view, high-quality schematic documents shall reflect this approach in their structure and shall provide at least three layers of abstraction that represent the system, function block as well as component level respectively. A clean schematic structure is indispensable for effectively applying design analysis techniques like block-FMEA, FTA, and component FMEDA and it also facilitates review processes.

For creating our circuit diagrams, we use the popular Altium Designer software tool, with which we already gained a lot of experience in the past 16 years.

We are using LTSpice by Analog Devices (previously Linear Technology) for simulation.

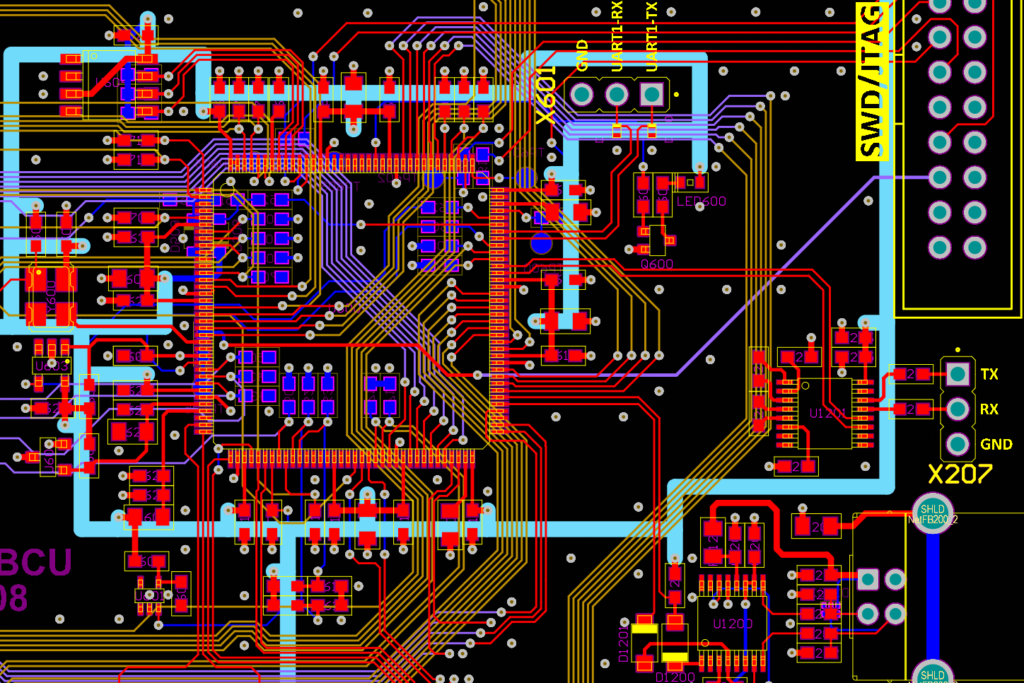

Layout Design

Several of our clients regularly count on our expertise when it comes to designing printed circuit boards in compliance with EMC testing standards. So far, we have been completed more than 200 successful PCB designs. In many projects, in addition to EMC properties, mechanical stress, as well as optimal thermal properties, were also important considerations. Our highest complexity PCB job was a safety-related extension board for variable frequency drives with the following key parameters:

| Physical dimensions: | 127 mm x 88,9 mm (5.00 inch x 3.5 inch) |

| Number of Cu layers: | 10 |

| Number of Components: | 1783 |

| Number of Connections: | 3402 |

| Assembly: | double-sided (SMT) |

For layout design, we use Altium Designer. Our team has over 16 years of experience in creating professional layout with Altium.

Hardware Tests

At the moment our hardware test capabilities are limited to function and module tests. We plan to extend our services shortly with thermal imaging and EMC Pre-Compliance tests.

Concerning EMC, Electrical Safety, and Environmental (e.g. temperature, shock, vibration, etc.) testing we rely on third parties.

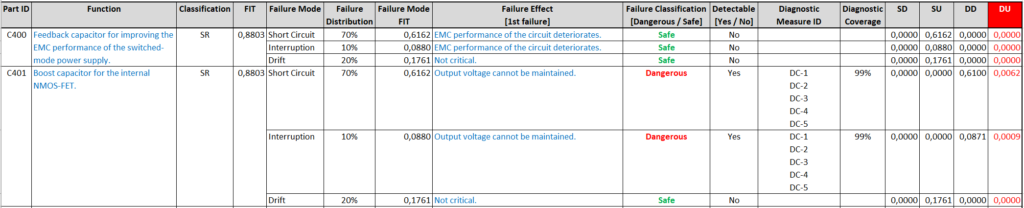

FMEDA

Safety standards (e.g. IEC 61508, ISO 26262, etc.) require to use quantitative methods for providing evidence that a particular circuit meets its safety targets. In most cases, it means, that a so-called Failure-Mode, Effect and Diagnostic Analysis (FMEDA) must be carried out on the safety-related electronics. FMEDA can help you to identify design flaws and it provides among other parameters like the probability of dangerous failures of a particular safety function. Conducting FMEDAs requires experience and deep knowledge of circuit analysis.

Since the begining of 2024 we can offer our customers carrying out FMEDAs by using the OEMx-Tool by exida LLC.

Consultancy and Review

We are happy to assist you also with consultancy and review services in connection with the hardware development activities listed above. Please feel free to contact us.